When compared to competitors, the Twister Food Waste Depackager and Separator is breaking into new markets thanks to its low microplastics output and low energy consumption.

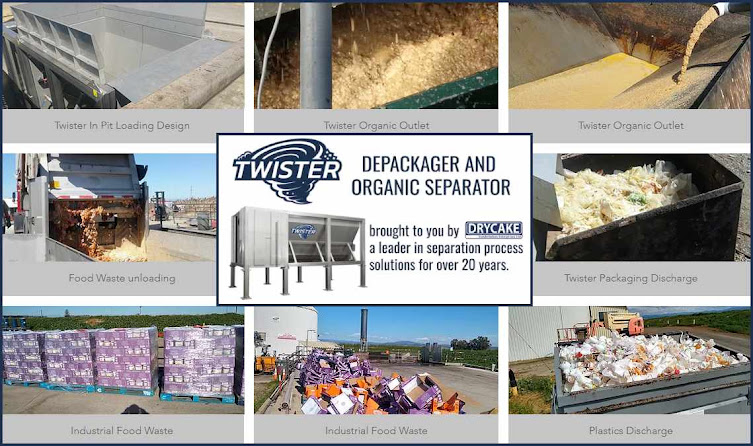

Twister announced today that their innovative Food

Waste Depackager and Separator has been purchased by new customers in Europe

and Asia. In the increasing EU and Asian markets, the small-footprint,

low-energy-use plastic waste reprocessing facility has established itself.

Since 2016, it has been in the works. It's a

decentralised organic processing system with exceptional separation performance

that was recently introduced in Canada.

Each opened, empty, and full box is ejected. The

"Twister" effect produces clean food waste that is free of

microplastics and suitable for anaerobic digestion.

"We wanted something distinctive for Drycake's

Twister," explains Mark Vanderbeken, Chairman and Founder of Drycake®.

"Anyone familiar with the food waste

depackaging industry will have noticed that everyone else looks to start their

depackaging and separation of source-separated organics by reducing particle

size." This is how most competing depackagers avoid congestion. They mill,

macerate, cut, or shred the plastic to make it into little pieces. Larger

pieces, on the other hand, are easier to separate than tiny ones, so why not

combine the depackaging and separation processes?"

Food Waste

Depackager Separator from Twister (TM)

So DryCake went back to the drawing board and came

up with a method that doesn't require any cutting and isn't dependant on reducing

particle size by processing plastic. In actuality, they use shear forces and

vibration to open and remove biological matter in a high-speed vortex, causing

as little injury as possible while making as little microplastics as possible.

As a result, it has established itself as a market

leader in terms of sustainability by reducing the risk of environmental damage

caused by plastic pollution. Due to rising evidence of "ocean microplastic

ingestion," which is hurting ocean plankton and the food chain that

sustains all marine life, Drycake adopted this course of action.

Slicing, bashing, and crushing these materials

likewise consumes a lot of energy. Hammer mills, blades, and knife openers all

have moving components that wear out and need to be replaced. As a result, the

Twister only has a few moving parts.

"It must be preferred to avoid breaking up

plastic wrapping wherever possible."

Mark continued, "Then you won't manufacture

those microplastic particles in the first place."

As a result, Drycake predicted that this invention

would be in high demand right away. This company has strong prospects to

disrupt the market and become the industry-standard depackager provider in

Europe and Asia, with considerable environmental benefits.

On the one hand, they want to provide their clients

the option of running sustainable plastic recycling businesses, reprocessing

garbage into resin for use in new packaging as part of the "circular

economy," which is vital to averting runaway climate change. While also

providing biogas facilities with a high-quality organic paste.

They may offer this mixture, or "organic

soup," as feedstock to anaerobic digestion plant operators, allowing them

to create renewable energy in the form of biogas refined to biomethane.

Renewable Natural Gas (RNG) is compressed biomethane that may be injected into

town and city gas mains to heat our homes.

It's also ideal for use as a low-emission

transportation fuel throughout the transition to hydrogen technology.

Twister is also a novel concept, as its target

market is larger than city/regional MRFs and ERFs (Energy Recovery Facilities/

Incinerators). The small size is ideal for several locations around a city,

reducing RCV travel distances, lowering collecting costs and emissions, and

improving food waste collection efficiency.

Waste collection employees will spend more time on

the street collecting rubbish and less time sat in the cabs of their RCVs en

route to the MRF ERF or transfer station as a result of the Twister unit

distribution. Drycake will also design the entire process, as well as the

facility, if necessary.

Twister's low energy use, low carbon footprint,

simple maintenance, and high uptime are all features they wish to impress their

clients with. It's a sound long-term investment that's also environmentally

friendly.

In fact, supermarkets, organisations, and

institutions that run catering facilities, as well as clients in the food and

beverage industry, may discover that purchasing just one Twister unit will help

them achieve their sustainability goals. As a consequence, their company's

carbon footprint is reduced, and they may proudly showcase their really green

achievements for years to come.

It's always a risk to try anything new, but they

feel it's one worth taking. In this circumstance, not least to contribute to

the global environment's preservation and to develop a product that would help

in the attainment of Net-Zero Carbon 2050 emission targets.

How Twister, a vortex-based food waste depackager, Outperforms Rivals

Twister Food Waste Depackager technology

accomplishes this in four different ways:

1. Combining two operations into a single unit to

save energy and water.

2. Reducing dependency on fossil fuels (e.g., oil),

which produce much more "greenhouse gas" carbon when things are made

from virgin plastic resins instead of recycled.

3. By transforming food waste into a plastic-free

paste or slurry that may be used to power a biogas plant, which provides

sustainable energy while emitting very little net carbon dioxide. This

eliminates the need to develop oil or gas geological deposits once more.

4. When organic slurry is digested and applied to

agricultural land, it decreases carbon emissions by reducing the requirement

for chemical fertilisers on the part of the farmer. Traditional fertilisers are

derived from geological deposits. They need a lot of fossil fuel to extract and

transport them, therefore this notion contributes even more to environmental

preservation.

Conclusion on the Twister Food Waste Depackager

Drycake has been a global leader in separation

solutions since 1995. Since its founding, it has provided market-disrupting

process equipment and design for sustainable waste reuse, recycling, and energy

recovery on a global scale.

This isn't the first time Drycake has gone against

the grain. They previously made a splash with the Plastifloat, a waste reuse

and materials recovery system for municipal and industrial wastewater. A

straightforward yet effective method for extracting plastic from liquids.

Drycake has grown into Europe and Asia, in addition

to previous sales in the Americas, and the Twister Food Waste Depackager is

aiming for global recognition. More information may be found in the following

article: Vortex Depackager and Separator by

Twister

Visit https://www.twisterseparator.com for more

details.

Also see https://drycake.com for more information.

No comments:

Post a Comment